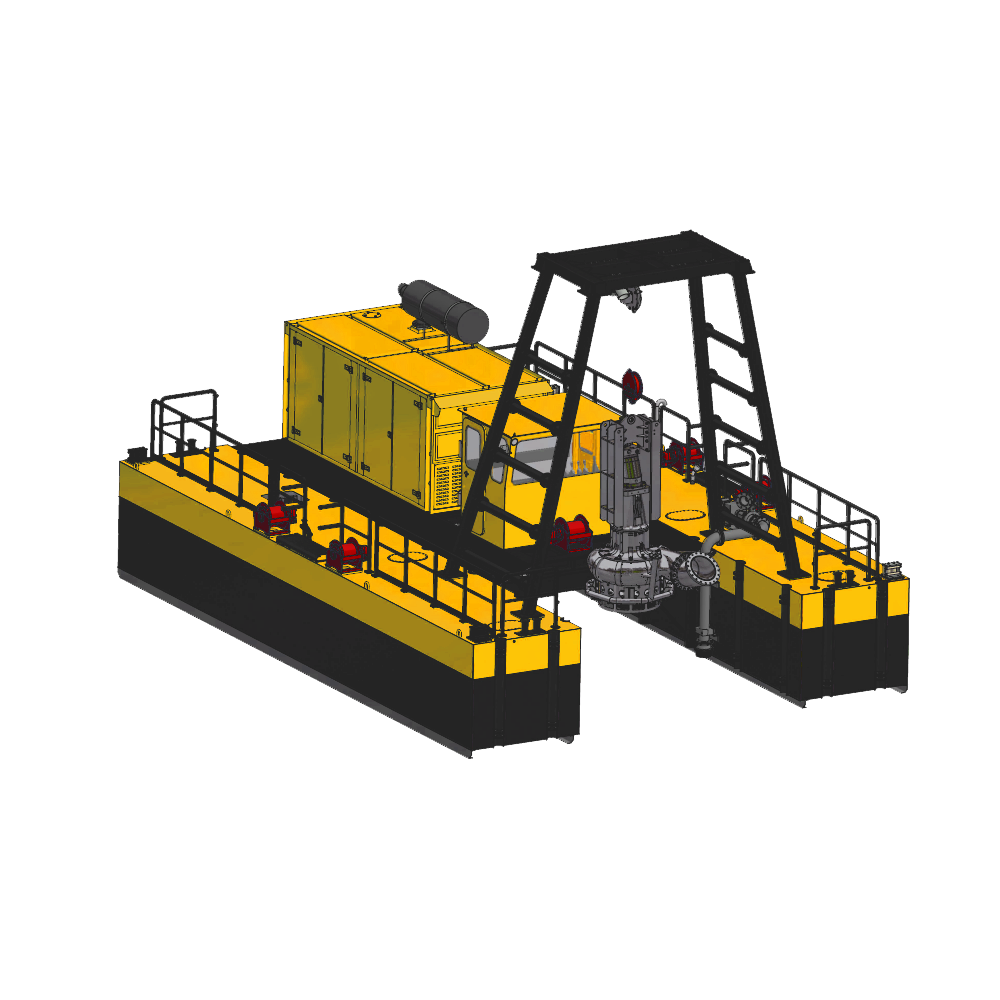

Dragflow DRH400 – High-Performance Dredging Solution

An efficient excavator dredge pump is essential for contractors handling slurry, sediment, and high-density materials in marine and mining environments. The Dragflow DRH400, supplied by Ace Centro Enterprises (ACE), delivers exceptional dredging performance through its advanced hydraulic technology and robust structural design.

This self-propelled dredge with steel cables is powered by the heavy-duty Dragflow HY400 hydraulic dredging pump, engineered to handle the toughest dredging operations with reliability and efficiency. Its modular pontoon design ensures stable operation at various depths, including environments with low pH slurry mixtures.

Built for Demanding Applications

ACE offers a complete range of electric and hydraulic submersible dredge pumps that can be integrated into dredging systems or adapted for excavator-mounted configurations. These systems are ideal for:

Harbor and port dredging

Canal and marina cleaning

Sand reclaiming

Mine tailing removal

Quarrying and aggregate processing

Waste pollution control

Heavy slurry pumping

Oil spill response

Tunneling and bentonite pumping

Sewage pumping

Dam and dike construction

Lake and channel dredging

Through its strong sales presence in the Arabian Gulf, ACE also supplies self-propelled dredgers with telescopic and ladder pump options across the Middle East and Africa for deep-sea dredging works at jetties, ports, and offshore platforms.

Product Specifications – Dragflow HY400 Pump

Advanced Agitator Technology

The HY400 pump features an advanced agitator system that enables efficient lifting and conveying of medium to high specific weight slurry mixtures, including:

Mud

Slime

Silt

Sand

Gravel

This makes it highly effective for excavator-assisted dredging operations requiring continuous slurry movement.

High-Capacity Slurry Handling

Handles slurries up to 1.7 specific gravity

Solids handling capability from 20 mm to 120 mm (5 inches)

Flow rates up to 4000 m³/hr

Pumping distances up to 1500 meters (longer distances achievable using booster pumps)

Dredging depths up to 300 meters, proven in dam construction projects

Engineered for Durability & Efficiency

Low Operating Speed

Reduced wear and extended service life due to optimized rotational speed.

Optional Protection Features

Temperature sensor embedded in the motor

Moisture sensor in the oil chamber

Best-in-Class Seal System

Unique lip seal system with front deflector

Teflon layers resistant to high and low pH conditions

Precision machining with grease injection points for extended seal longevity

Wear-Resistant Construction

All wear parts manufactured in High Chrome Alloy

Pump castings 100% made in Italy using premium-grade metallurgy

Electrical Options

Available in 50 Hz and 60 Hz electric versions to meet global standards

Why Choose the DRH400?

For contractors seeking a powerful excavator dredge pump solution or a fully integrated self-propelled dredging system, the Dragflow DRH400 offers:

High solids handling capacity

Deep-water operational capability

Extended pumping distance

Reliable steel cable positioning system

Long-term durability in abrasive environments

The DRH400 combines performance, engineering precision, and operational flexibility to deliver consistent results in even the most demanding dredging projects.

Excavator Dredge Pump DETAILED DRH400 SELF-PROPELLED DREDGE WITH STEEL CABLES